JE Cleantech takes electrifying journey to cleaner operations

From reducing water consumption to investing in EVs, the company is powering up on eco-friendly solutions

JE CLEANTECH Holdings has made a business out of helping companies clean their equipment. It is now on a journey of cleaning its own operations, but in a different manner of speaking.

The company makes custom cleaning machines and provides dishwashing services to the food and beverage (F&B) industry.

One of its goals is to help customers reduce their water consumption.

This is a complex goal given that JE Cleantech serves customers in the hard disk drive, semiconductor and industrial product manufacturing segments – which means it has to accommodate a range of customer demands.

For instance, some customers will only require visual confirmation that items are clean.

But others may send the cleaned products to test for factors such as their ionic content.

Navigate Asia in

a new global order

Get the insights delivered to your inbox.

“Imagine you would like to buy a hard drive that’s slim and light. It means all the media is getting closer and closer, so … any particles will destroy the whole thing,” said chief executive Elise Hong.

She likened the various forms of cleaning solutions the company manufactures to different “recipes” that aim to achieve different outcomes.

This is not unlike the various modes of a washing machine, which would have different programs suited to washing different types of loads and fabrics.

Within the 10 to 16 weeks it takes to create a machine for a client, the company will work with clients to figure out what it hopes to accomplish and create this optimum “recipe” for them.

The process could include working with customers to figure out how cleaning can improve their current operations.

A company looking to spray paint its components, for example, may find a deeper wash more beneficial as this could increase its yield by creating a smoother surface and improve paint adherence.

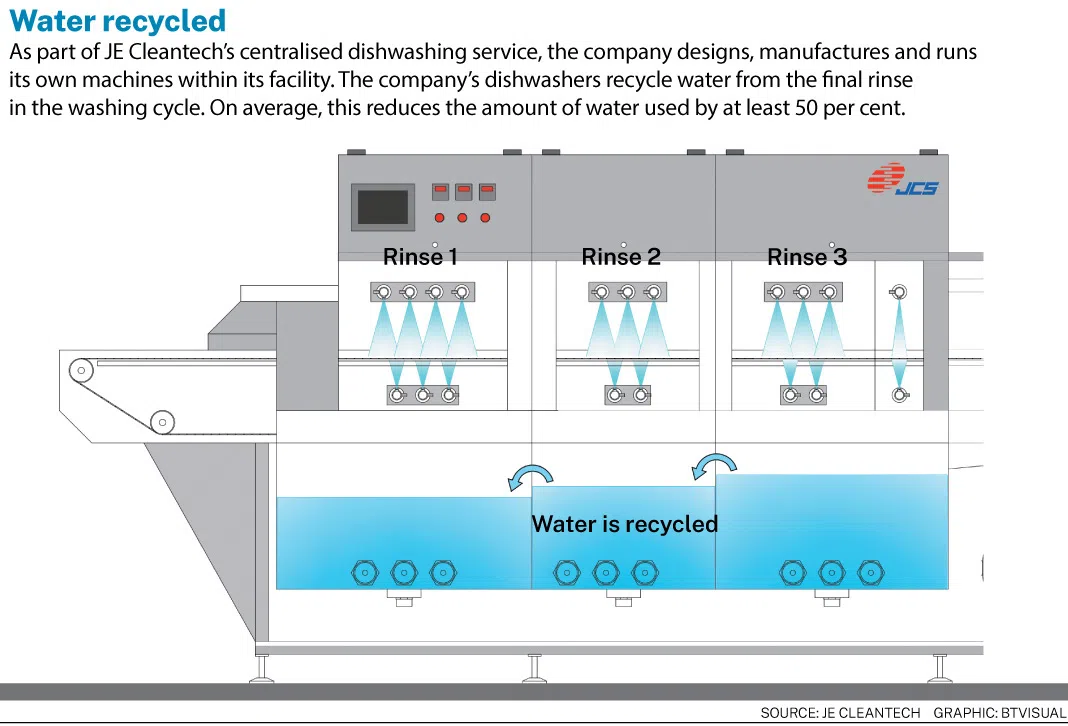

Meanwhile, with its dishwashers, JE Cleantech aims to design machines that recycle as much water as possible in the washing process.

While the amount of water saved per wash depends on customer requirements and different situations – such as how soiled certain dishes are – the company is usually able to halve the amount of water used.

Cleaning up on carbon

Beyond optimisations for its clients, JE Cleantech is investing in reducing its own carbon footprint.

The company has begun to electrify its fleet of vehicles. Its first electric vehicle (EV), a BYD eT3 electric van, was financed with a green loan from UOB in the first quarter of this year.

“It requires less energy and saves costs too,” Hong said, adding that the company has cut fuel and maintenance costs by about 60 per cent.

Since the electric motors that drive EVs tend to have fewer parts than those with internal combustion engines, they tend to be simpler and require less maintenance.

EVs also require fewer fluids, such as engine oil, that need to be replaced. Brake wear is also significantly reduced if the vehicle employs regenerative braking.

UOB head of sector solutions group Bonar Silalahi noted that the adoption rate of electric goods vehicles in Singapore has increased from 2.5 per cent in 2021 to 30 per cent in April this year.

“With the increasing imperative for businesses to fulfil their net-zero targets and a wider range of vehicle models available to meet user requirements, we have seen a sharp increase in the take-up of green loans to finance the switch to electric vehicles,” he said.

In January, JE Cleantech also installed solar panels at its manufacturing facility and office in Woodlands. These are estimated to generate about 232 megawatt-hours of energy per year, which should offset more than half of the energy consumed at the site.

Hong noted that members of the Singapore Precision Engineering & Technology Association, of which she is chair, saw their energy bills more than treble when volatility in the electricity markets led to the exits of some electricity retailers.

Solar energy is therefore a good way to provide the company with some energy security.

“At least if anything happens, you still have some energy to use,” she said.

Other efficiencies

JE Cleantech was hit hard during the pandemic. Revenues declined 31 per cent to S$14.8 million in FY2021, before rising 26.2 per cent to S$18.6 million in FY2022.

Net income also declined from S$1.7 million in 2020 to S$2,000 in 2021, before rebounding to S$1.2 million in 2022.

In its bid to generate cash flows that are more consistent, the company hopes to expand its centralised dishwashing operations.

The company sees steady growth in the demand for centralised dishwashing services.

Between 2020 and 2022, the share of its revenue generated from the provision of centralised dishwashing and ancillary services has grown from 20.8 per cent to 38.6 per cent.

While the pandemic hurt demand for such services, as dining out was banned or restricted, she sees demand increasing in the long run as older workers retire and F&B operators find it more difficult to hire younger workers to do such jobs.

The manpower crunch that F&B operators face has also led to a greater push for the adoption of automation, even if it may not necessarily lead to savings.

Furthermore, the use of mechanised dishwashers ensures that dishes continue to be washed efficiently – unlike human workers who will tire out after a few hours of work.

By centralising the cleaning of utensils, food courts and other F&B establishments can also save on space that was previously dedicated to dishwashing.

Beyond dishwashing, Hong said the company is also looking at growing its revenue more steadily by creating other products for different industries with the company’s expertise in cleaning.

In the meantime, JE Cleantech continues to look for ways to innovate on its machines and processes.

In 2018, the company worked with entities such as the Singapore Institute of Manufacturing Technology to develop cleaning systems for trains.

The cleaning system uses artificial intelligence to evaluate the cleanliness of trains before and after they are cleaned. This removes the need for maintenance teams to manually check the trains.

The company also optimises its manufacturing process in various ways. For instance, cuts with the laser machine are planned so that the machine can cut more parts with a single piece of material. This saves time on loading and unloading the machine.

JE Cleantech also invested in faster computer numerical control machinery in 2021, to reduce the amount of time needed to cut parts for machines.

This is the third of a 5-part Green Business series, in collaboration with UOB, exploring sustainability trends across businesses and industries.

Decoding Asia newsletter: your guide to navigating Asia in a new global order. Sign up here to get Decoding Asia newsletter. Delivered to your inbox. Free.

Copyright SPH Media. All rights reserved.