Oilfield Services & Supplies’ next frontier is going deeper into surface engineering

The company is exploring a new coating process that could boost its competitive edge

IN MORE than two decades, Oilfield Services & Supplies (OSS) has evolved from a single workshop in Singapore to a regional company that serves some of the biggest names in the oil and gas industry.

Its expansion in the Asia-Pacific region and beyond means that the majority of its revenue now comes from overseas.

Its diversification efforts are not just geographical. Although most of its revenue still comes from the oil industry, OSS is developing a new technology that can take it into new sectors and add a more responsible spin to the business of drilling for oil.

Drill fit

The company’s core business is precision machining and manufacturing drilling tools for the oil industry, with around 95 per cent of revenue from oil and gas projects.

In short, the company makes and repairs “anything involved with below-the-ground drilling”, said managing director Kay Ong.

This requires not just precision machining, but also a deep knowledge of metallurgy and surface engineering, he added.

Navigate Asia in

a new global order

Get the insights delivered to your inbox.

OSS supports oilfield service companies that work for oil majors, though its client list is confidential. It has followed the oil – that is, its clients – to set up a facility each in China, India, Kazakhstan, Malaysia and Thailand, and two facilities in Indonesia.

Overseas operations account for 60 per cent of revenue. OSS intends to raise this to 70 per cent over the next three years, through more expansions.

Most of its overseas locations began as repair workshops providing basic services, but have evolved into a way to maintain client relationships and monitor industry demands.

SEE ALSO

OSS business development manager Kenneth Loh noted, “We’re not a market mover, so we try to follow (the clients) very closely. We think about our market, our customers, where they are, where they need us. That’s how we have carved out a niche for ourselves.”

Having overseas outposts helps OSS understand the market.

“At (overseas locations, our staff) can be in touch with customers daily, understand what needs to be done and gain feedback, which is passed to the managing committee in Singapore. Then we decide holistically, as a strategy, what we (should) double down on or invest in,” said Loh.

One example is India, where OSS has been since 2007. Having gained experience and market knowledge there, the company is now investing in a major facility in Mumbai.

Set to open in the first quarter of 2025, this will be the first facility that is fully owned by OSS, as its existing facilities are all joint ventures with local partners.

The 50,000-sq-ft facility costs around S$4 million, and will increase the group’s production capacity by around 25 per cent.

Loh said that the lower cost base that India provides, in areas such as manpower, will help OSS be more competitive.

Beyond Asia, OSS plans to enter the Middle East and Africa. As the company already repairs a considerable amount of parts that are shipped to Singapore from projects in the Middle East, a satellite presence there would be feasible, added Loh.

Singapore spring

OSS is also trying to gain a new edge – literally – over its competition.

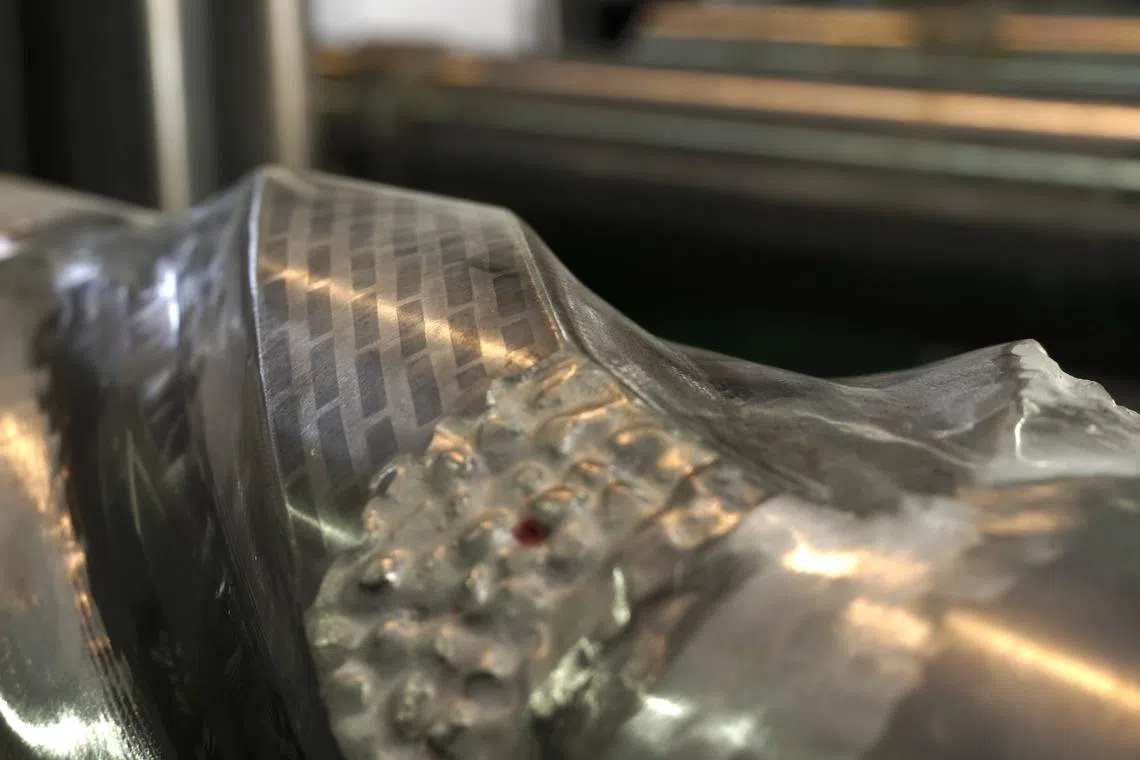

In addition to machining and repairs, a third pillar of its business is surface engineering, which involves the coatings of drill bits and other machine parts.

Usually, oil drill bits are coated in a hard-wearing tungsten carbide layer, making them far tougher than plain metal ones.

But tungsten has been designated as a “conflict mineral” by the US and European Union. In areas of conflict in Africa, tungsten mining has been used to fund armed groups, human rights abuses and more.

Under US and EU regulations, tungsten must be sourced from responsible and conflict-free suppliers.

Instead, OSS is working with research institutes to create a novel coating process that does not use the mineral at all.

The company hopes to see positive results in three or four years’ time, said Loh.

A better coating process could also improve the life and efficiency of machinery parts, supporting its clients’ sustainability efforts.

This successful surface engineering project could also provide a springboard for OSS to enter adjacent industries where surface engineering matters, such as the maritime and defence sectors.

As OSS would have ownership of the new process, it could use this as a selling point to increase its market share, or license it out to others.

Such research collaborations, observed Loh, are why Singapore will remain the centre of technology and excellence for OSS, despite the company’s significant overseas presence.

OSS has established itself as a trusted name thanks to the strength of the Singapore ecosystem, which includes research institutes, local companies and other players in the manufacturing value chain, he added.

“It’s purely because they trust us... our reputation... and it is a Singapore ‘thing’, too. I think (clients) value the quality and also the speed of delivery that OSS Singapore offers.”

Decoding Asia newsletter: your guide to navigating Asia in a new global order. Sign up here to get Decoding Asia newsletter. Delivered to your inbox. Free.

Copyright SPH Media. All rights reserved.