A new era in diamond transparency

JEWELLERY

Corinne Kerk

BY THE END OF THE 19th century, rings were nothing like what we see today.

They were heavily embellished with ornate details, and had gemstones set low against the band. It’s hard to imagine being limited to such ring designs today or proposed to with one of them.

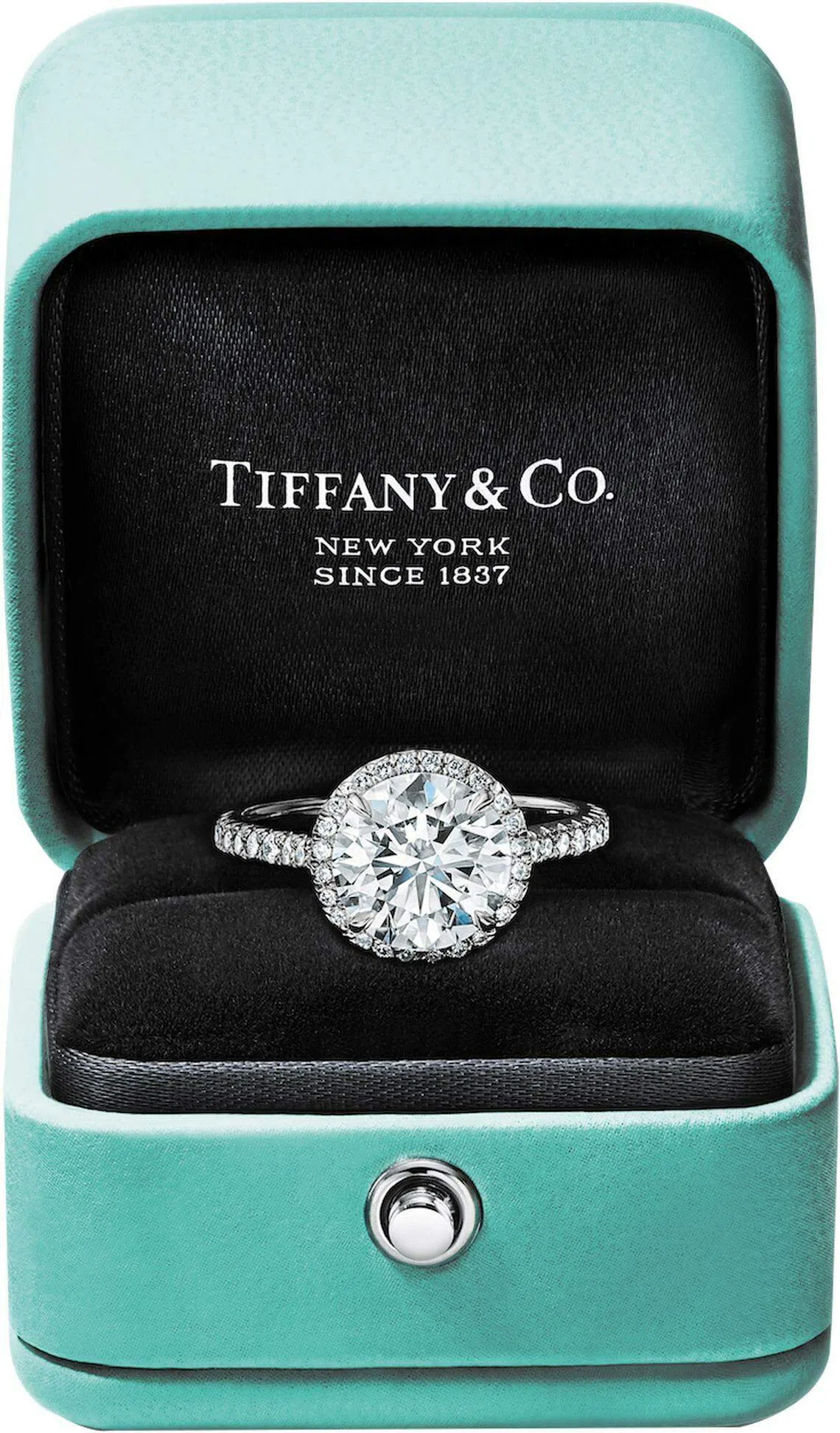

Thankfully, there was Charles Lewis Tiffany, who chose to go against the grain. Eschewing overly elaborate designs, the founder of Tiffany & Co introduced the iconic Tiffany Setting in 1886. It was a radical departure from ring designs then, with its distinctive knife-edge band and delicate six-prong setting expertly engineered to allow a sparkling diamond to take centre stage.

It quickly became a universal symbol of love and commitment, and a classic, solitaire diamond engagement ring that set the standard against which all engagement rings came to be measured. A design masterpiece, the Tiffany Setting was the first to lift the diamond off the band. All because the American luxury jeweller was looking for innovative ways to showcase its diamonds – a gem on which it was, and remains, an authority.

Unparalleled mastery

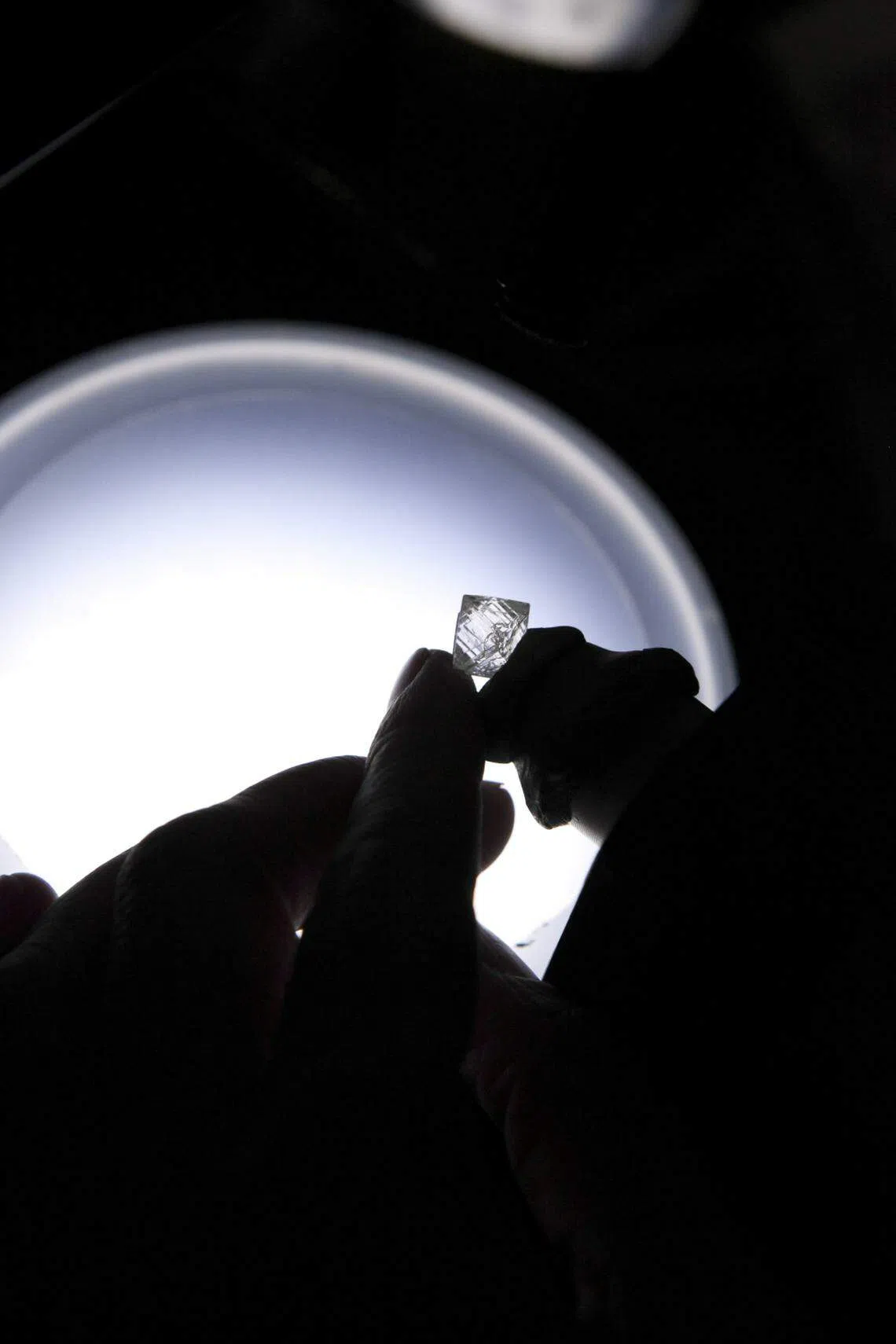

Tiffany’s industry-leading craftsmanship sets its diamonds apart, with the stones entrusted to experienced craftspeople from the moment they are unearthed. The jeweller employs some 1,500 expert cutters and polishers in its own state-of-the-art workshops.

Navigate Asia in

a new global order

Get the insights delivered to your inbox.

This is to ensure excellence of cut is obsessively considered to maximise brilliance, dispersion and scintillation – not just carat weight. Operating its own workshops also provides assurance that its sourcing practices honour the places and people that provide these precious stones.

On top of that, 99 per cent of Tiffany’s international manufacturing workforce are hired from local communities, ensuring that wherever the jeweller operates, the populace benefits from employment opportunities and skills transfer.

Transparent provenance

For Tiffany, it isn’t good enough that its diamonds are beautifully crafted, or even that they are “conflict-free”, that is, not illegally traded to fund conflict in war-torn areas. What is equally important is that consumers are aware of where these precious stones – many of which will become heirlooms – come from.

So in 2019, the jeweller announced that it will disclose the provenance – the region or country of origin – of its newly-sourced, individually registered diamonds. By 2020, it also started sharing the gems’ craftsmanship journey, which includes where the stones are cut and polished – an industry first.

With its Diamond Source Initiative, Tiffany is tracing each of its individually registered diamonds (0.18 carat and larger) by a unique “T&Co” serial number etched by laser and invisible to the naked eye, and providing consumers geographic sourcing information specific to their diamond. Knowing provenance, the jeweller believes, is critical to ensuring its diamonds are among the most responsibly sourced in the world.

Where provenance is unknown – such as heritage stones that predate this policy – Tiffany will provide confirmation that the diamond was sourced with industry leading practices.

Years of intentional investing

A high level of transparency is only possible if one had the foresight to invest early. And that’s exactly what Tiffany did – putting resources into vertical integration and prioritising its supply chain transparency since 1999. This has resulted in a degree of supply chain transparency that is without equal among global luxury jewellers.

Some 80-90 per cent of Tiffany’s individually registered diamonds by volume have been supplied through its diamond workshops in Belgium, Botswana, Mauritius, Vietnam and Cambodia. Craftspeople in these locations plan, saw and/or cut and polish rough diamonds from known, responsibly managed mines, most of which are in Botswana, Canada, Namibia, Russia and South Africa.

For the remaining 10-20 per cent, Tiffany’s trusted suppliers of polished diamonds have complied with Tiffany’s Diamond Source Warranty Protocol, which warrants the diamonds did not originate in countries with diamond-related human rights concerns, such as Zimbabwe and Angola. This is even though such diamonds are accepted under the Kimberley Process, which certifies that they are not “conflict” diamonds.

These suppliers are also required to go beyond a warranty of “conflict-free” to affirmatively state the geographic source of any polished diamonds sold to Tiffany including region or countries of origin.

Tiffany also has its own gemological laboratory in New York and five jewellery manufacturing workshops in North America, to ensure its own superlative standards are met.

Diamond Kings

The premier purveyor of diamonds, Tiffany has handcrafted the most beautiful specimens in the world since 1848, with Tiffany dubbed “Diamond Kings”.

With a discerning eye for outstanding quality, Tiffany purchased one of the world’s largest and most celebrated fancy yellow diamonds in 1878. The 287.42-carat rough stone was cut into a cushion-shape brilliant weighing 128.54 carats with an unprecedented 82 facets – 24 more than the traditional 58-facet brilliant cut.

Today, the Tiffany Diamond remains one of the most important gemstones in the world and exemplifies Tiffany’s legacy of visionary artistry and innovation in craftsmanship.

JOURNEY OF A TIFFANY DIAMOND

From the time a rough diamond is unearthed until it is set on a ring and placed in a signature Tiffany Blue Box – thousands of miles would have been traversed across the world.

Here, we take an inside look at what goes on behind the high quality, beautiful artistry and responsible practices that Tiffany demands of itself.

Step 1: Responsible sourcing

Tiffany sources its rough diamonds from countries such as Australia, Botswana, Canada, Namibia, Russia and South Africa. Diamonds from areas of concern such as Zimbabwe and Angola are prohibited. Approximately 65 per cent to 75 per cent of its stones are rough diamonds, which are sourced either directly from a known mine or from a supplier with a limited number of known mines.

Step 2: Superior standards

Only 0.04 per cent of the world’s gem-grade diamonds meet Tiffany’s exacting standards. All the rough stones that pass muster are sent to its workshop in Antwerp, Belgium, which is also the jeweller’s headquarters for diamond operation.

Here, each individual stone’s origin is recorded, before the diamonds are sorted for size, colour, clarity and fluorescence. A unique design is then mapped for every piece to ensure the most beautiful diamond possible.

Step 3: Making the cut

Tiffany owns workshops in Botswana, Mauritius, Belgium, Vietnam and Cambodia, where its well-trained craftspeople cut and polish its diamonds with great accuracy and artistry. It also procures select polished diamonds from trusted suppliers who comply with its traceability, quality, social and environmental standards.

The jeweller hires locally, invests in communities and provides a living wage for employees in developing countries. Its owned or approved diamond cutting and polishing facilities offer safe and healthy work environments; and adhere to health and safety standards that, in many places, go above and beyond local laws.

Step 4: Quality assured

Tiffany diamonds are meticulously inspected and evaluated at the network of Tiffany Gemological Laboratories in the US, Cambodia, and Vietnam, ensuring every stone meets superlative grading requirements, standards which are established and assured in New York.

Step 5: Set to sparkle

Tiffany sets the majority of its diamonds at its workshops in the US; each facility meeting high standards for safety, cleanliness and a productive, welcoming environment. Working in such surroundings with great accuracy and artistry, a diamond setter pairs each unique diamond with its ideal setting, individually adjusting each prong and basket to reveal the beauty of the stone.

Step 6: An icon is born

A Tiffany diamond is now ready to be placed in its Tiffany Blue Box and bag, made with paper from sustainable sources, including Forest Stewardship Council-certified and recycled materials

.

A CUT ABOVE THE REST

Every diamond is unique, and like a human fingerprint, is distinguished by its individual characteristics. To assess the quality of a diamond, the globally accepted standards of the 4Cs come into play.

They are colour, clarity, cut and carat weight. Colour refers to the natural tint inherent in white diamonds, while clarity is a measure of the stone��’s purity and rarity. Cut is determined by how a diamond’s facets interact with light and carat is the diamond’s weight

The importance of cut

Of the 4Cs, the most important of all is cut.

Cut is determined by symmetry, proportion and polish, and more than any other factor, it dictates the beauty of the stone. At Tiffany, the brilliance of a stone, whatever its size, is always prioritised over its carat weight.

For a diamond to sparkle beautifully, a good cut is of utmost importance. If it is cut poorly, it will appear dull, even if it has a high colour and clarity grade. A well-cut diamond, however, will reflect and refract light for maximum brightness and sparkle.

At Tiffany, its highly-skilled artisans are committed to crafting the most expertly proportioned diamonds. The result? All its round brilliant engagement diamonds are rated triple excellent.

The Tiffany difference

A triple excellent cut is the highest grade possible for round brilliant diamonds. To receive this exceptional grade, a diamond must meet Tiffany’s “excellent” standard across three factors – precision of cut, polish and symmetry. A triple excellent diamond maximises light return, or brilliance, resulting in a stone that sparkles beyond compare.

The fact that cut is the only one of the 4Cs affected by human hands, is testament to the unparalleled expertise, precision and technique of Tiffany’s master graders and artisans. Together, they ensure that Tiffany diamonds are truly set apart.

After all, two diamonds may have the same clarity, colour and carat weight, but cut is what determines whether one is superior to the other.

Types of diamond cuts

All Tiffany diamonds are masterfully and carefully cut to maximise brilliance. Whatever the diamond shape, there are three diamond cuts used to craft them – brilliant cut, step cut and mixed cut.

The brilliant cut is the most popular facet arrangement and is made of triangular and kite-shaped facets, all arranged to optimise brilliance or light return. The round brilliant diamond, which has 57 to 58 facets, is the most brilliant of the diamond cuts. Cushion, oval, marquise, pear and heart-shaped diamonds are also cut using the brilliant faceting style and are similar to the round brilliant in degree of sparkle.

Step-cut diamonds, on the other hand, have trapezoidal facets that run parallel to the diamond’s girdle, resembling a set of stairs. This faceting style emphasises a diamond’s colour and clarity. The most well-known step cut is the emerald cut.

Finally, mixed cuts combine brilliant and step-cut facets. The Tiffany True diamond, for instance, is a mixed cut with a crown made entirely of step cuts and a brilliant-cut pavilion.

Fancy a classic Tiffany diamond ring on your finger or for a loved one? Book an appointment with a Tiffany diamond expert at www.tiffany.sg

Decoding Asia newsletter: your guide to navigating Asia in a new global order. Sign up here to get Decoding Asia newsletter. Delivered to your inbox. Free.

Copyright SPH Media. All rights reserved.