Singapore aims to house the most globally competitive plants

EDB assistant MD says critical mass reached for advanced manufacturing to take off in a big way here

Singapore

SINGAPORE has a vision: That is all factories housed in the Republic will be the most globally competitive, efficient and productive for companies.

These are bold goals but work is underway to move towards that vision through advanced manufacturing, the Economic Development Board's (EDB) assistant managing director Lim Kok Kiang told The Business Times in an exclusive interview.

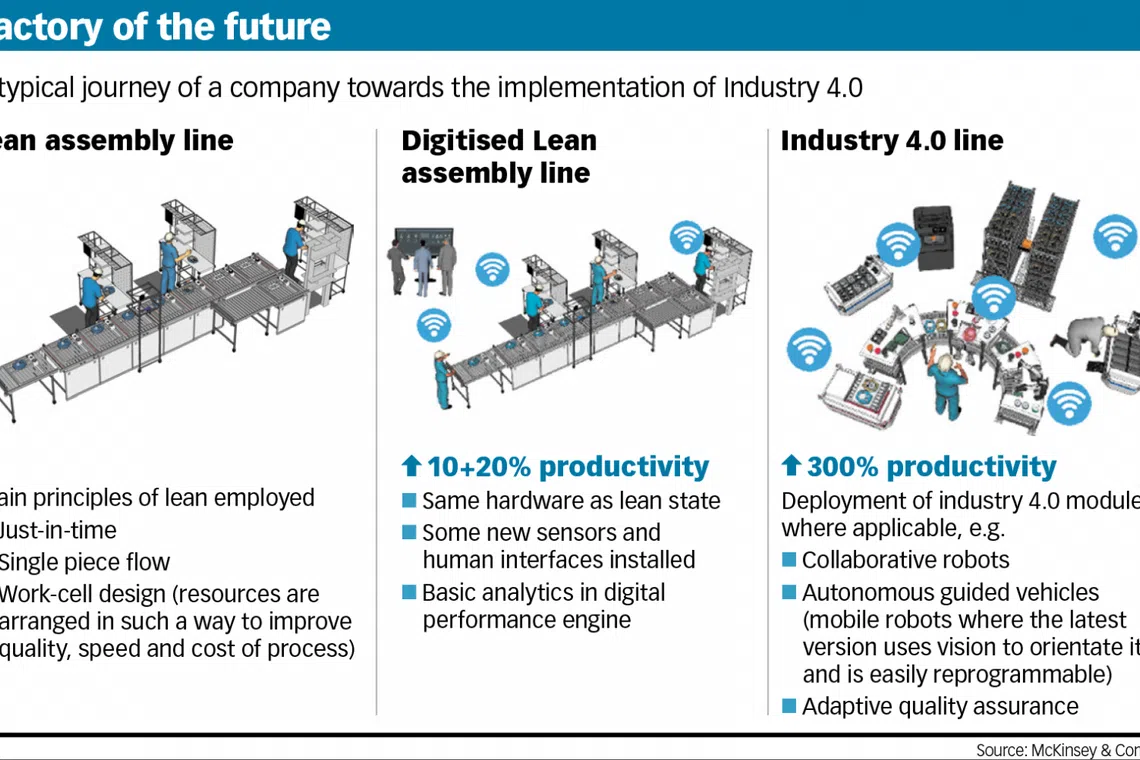

For one thing, the manufacturing sector here is at an inflexion point, having reached a critical mass for the fourth industrial revolution, known as Industry 4.0, to take off.

Advanced manufacturing is a fusion of new automation technologies, such as robotics, additive manufacturing and autonomous guided vehicles, with industrial Internet of Things, like cloud computing, augmented reality and machine learning.

Said Mr Lim: "If we are successful, hopefully all plants in Singapore, especially the bigger plants, will be the most competitive plant for that company on a global basis."

Navigate Asia in

a new global order

Get the insights delivered to your inbox.

There are currently some plants in Singapore which already fit that description. "Imagine if all plants in Singapore are actually that way,'' said Mr Lim. "The existing plant can also, through the adoption of all these technologies over a period of time, be the most competitive plant for that company on a global basis." This will ensure that the manufacturing sector continues to contribute 20 per cent to the country's economy.

The Committee on the Future Economy has identified advanced manufacturing as one of the key growth areas for Singapore. Under the Research, Innovation and Enterprise (RIE) 2020 plan, the government has set aside S$3.2 billion for advanced manufacturing and engineering.

Said Mr Lim: "We already have a big manufacturing base in Singapore, so we are not starting from zero. These companies are constantly looking at ways to improve their manufacturing operations ... because manufacturing is not just about labour cost anymore."

Singapore is a manufacturing base for a wide number of industries from semiconductors to motors to aircraft engines and even petrochemical plants, all of which are doing relatively well.

Productivity in the manufacturing sector is quite high compared to productivity in Singapore as an average, as the companies are competing on a global basis, Mr Lim noted.

"A company can choose to put their factory here or in China, Germany or Japan,'' said Mr Lim. Embracing technologies will make Singapore plants more productive, efficient and competitive. Doing that also works in Singapore's favour, as it helps mitigate issues related to labour and land constraints.

"If we want to continue to expand and be competitive in manufacturing, we must be able to do more with less because we are not able to compete on labour cost alone. And all these technologies are exactly enabling that," said Mr Lim.

A fusion of technologies and digitalisation enables factories to become smarter. Sensors are deployed in an industrial setting to allow the process to become more intelligent and interactive. Everything, from maintenance to quality control to monitoring energy efficiency, can be done in a more efficient way.

In predictive maintenance, for instance, sensors can detect when supplies are running low and automatically send out an order for them to be replenished, or they can detect and alert when certain parts need attention. In quality control, image sensors can pick up flaws better than the human eye, thus ensuring quality.

However, there is no one-size-fits-all, stressed Mr Lim, as each company adopts technology in a different way. He also emphasised that it is a continuous journey of improvements and enhancements, where new technologies are integrated over time to improve productivity.

Using technology also adds smartness in automation and opens up new possibilities, such as producing more variety with the same floor space, and new business models, such as customised products.

A certain degree of smartness is needed to attain a lot size of one, or customisation, which is where advanced manufacturing is moving towards.

A case in point is local small and medium enterprise, PBA Group, which has a smart factory that could manufacture its products with a lower production cost per unit than its factory in China.

Meiban Group has plans to invest about S$10 million to S$12 million to testbed solutions in robotics, automation and smart factory software, to achieve a 20 to 30 per cent rise in productivity, and subsequently scale them to its regional factories.

Mr Lim said: "There could be a potential export of technology and solutions, but the Singapore plant is not staying still. It is continuously making another level of improvement." In the past, technologies were successful elsewhere before they were replicated here.

He added: "Instead of us just being fastest implementor of technology, it could be that we are also working and evolving some of these technologies ourselves and exporting them to the other plants of these companies in the region and beyond from Singapore."

At the launch of Manufacturing Technology Asia 2017 held from April 4 to 7 at Singapore Expo, 25 companies - both manufacturing companies and technology providers - which have made strategic advanced manufacturing investments in Singapore were celebrated and recognised.

Among them was Shell Singapore, which uses drones for site inspections, data analytics and mechanisation to support its maintenance activities. Chevron Oronite's use of a wireless plant network with mobile tracking devices for employees is expected to save 30,000 man-hours each year.

As advanced manufacturing gathers pace, new jobs like data scientists are created, while low-skilled, manual intensive jobs will give way.

Said Mr Lim: "It is about technology working with people, not technology replacing people. It needs both the workers and the engineers to bring out the best of whatever technology there is.''

Two model factories under public-private partnership with A*Star will also be set up to help SMEs with technology adoption. One will be at the Singapore Institute for Manufacturing Technology (SIMTech) while another will be at the Advanced Remanufacturing and Technology Centre (ARTC).

READ MORE:

Copyright SPH Media. All rights reserved.